There are several factors—such as thread reach, thread diameter, the insulator nose projection and whether the spark plug incorporates a gasket or is of the conical type—to consider when choosing the correct spark plug for your needs.

In most cases, it is not until the engine is modified, or the compression is raised significantly, that stock ignition systems and spark plugs begin to show signs of being inadequate. At this point, a variety of factors determine which spark plug will be best suited for a particular configuration. In these modified engines, specific electrode/tip combinations, electrode materials and colder heat ranges can provide measurable gains in power. If your vehicle has had extensive modifications, it would be best to seek the advice of the manufacturer of your vehicle, the aftermarket supplier who manufactured your modifications or your service technician.

A common misconception is that changing spark plugs will result in a large power increase. In most cases, removing even seriously worn out spark plugs will only result in very modest power gains, typically about 1-2% of total engine output. This could be even less for computer-controlled vehicles, primarily because most newer vehicles have more powerful ignition systems and the vehicle’s computer can make adjustments so that vehicle operation seems smoother and more seamless.

Many people think that simply supplying more spark to the firing tip can and will combust more fuel. What they don’t understand is that most newer car engines are so efficient that they are already burning all of the available fuel. Simply adding more spark voltage can’t burn more fuel because there is no more fuel to burn.

When a stock or near-stock engine is given a fresh set of spark plugs, peak efficiency is restored. The power gains that come from this restored state of tune are usually minimal. Any company that tells you that their spark plug will provide significant gains in power in a stock or near-stock engine is making blanket statements that may not be supportable.

Unfortunately, there is no single answer to this question. As spark plugs grow older, they lose their sharp edges as material from the centre and ground electrodes is slowly eroded away. As the gap between these two points grows, the voltage required to bridge the gap increases proportionately. Even the best ignition systems will be strained to supply enough voltage to completely burn the fuel. It is at this point, when fuel is being left unburned, that the time has come to change spark plugs.

Replacing worn out spark plugs with new ones (with sharp new edges) effectively restores the ignition system’s efficiency. Misfires are reduced, power is restored, economy of operation is enhanced and emissions are reduced.

The best guide is the manufacturer’s recommendation for your vehicle, as this particular service varies from brand to brand and model to model. In the absence of this information or in conjunction with it, you can rely on the advice of a service technician who is familiar with your type of vehicle. In the best of all worlds, this would be a service technician who is also familiar with the vehicle you own. If you find a good service technician, whether dealer or independent, stick with them. The better he knows your personal vehicle, the better he will be able to diagnose and service it. The end result is very much like a doctor-patient relationship and, in the long run, you will have a healthier vehicle.

It depends on the modifications. The term “modified” refers to those engines that have received bolt-on improvements that may or may not raise the engine’s total compression ratio. These can include turbo charging, supercharging, nitrous oxide injection, the use of smaller-chambered cylinder heads, modified piston configurations, free-flowing cylinder heads, change of induction components and/or the use of different fuel types and octane. These kinds of modifications generally require a change from stock spark plugs.

Modifications that will typically not require specialized plugs (in most cases the factory installed plug will be more than adequate) include adding a free-flowing air filter, headers, mufflers and rear-end gears. Basically, any modification that does not alter the overall compression ratio will not usually necessitate changing plug types or heat ranges. Such minor modifications will not significantly increase the amount of heat in the combustion chamber, hence, a plug change is probably not warranted.

However, when compression is raised, along with the added power comes added heat. Since spark plugs must remove heat and a modified engine makes more heat, the spark plug must remove more heat. A colder heat range spark plug must be selected and plug gaps should be adjusted smaller to ensure proper ignitability in this denser air-fuel mixture.

Typically, for every 75-100 hp you add, you should go one step colder on the spark plug’s heat range. A hotter heat range is not usually recommended except when severe oil or fuel fouling is occurring.

Being able to “read” a spark plug can be a valuable tuning aid. By examining the insulator firing nose colour, an experienced engine tuner can determine a great deal about the engine’s overall operating condition.

In general, a light tan/grey colour tells you that the spark plug is operating at optimum temperature and that the engine is in good condition. Dark colouring, such as heavy black wet or dry deposits, can indicate an overly rich condition, too cold a heat range spark plug, a possible vacuum leak, low compression, overly retarded timing or too large a plug gap.

If the deposits are wet, it can be an indication of a breached head gasket, poor oil control from ring or valve train problems or an extremely rich condition—depending on the nature of the liquid present at the firing tip.

A spark plug is considered fouled when the insulator nose at the firing tip becomes coated with a foreign substance such as fuel, oil or carbon. This coating makes it easier for the voltage to follow along the insulator nose, leach back down into the metal shell and ground out rather than bridging the gap and firing normally.

Many factors can contribute to spark plug fouling. The air-fuel ratio may be too rich as a result of incorrect carburettor adjustment or a poorly performing fuel injection system. Worn piston rings or valve seals may allow too much oil to leak into the combustion chamber, leading to oil fouling. The ignition system may not be performing properly. Prolonged idling or continuous low-speed driving may keep the spark plug from reaching its optimum operating temperature. Using too cold a spark plug can lead to the same problem. Finally, a dirty air cleaner can create a too-rich condition which can lead to fouling.

Fuel, oil and carbon fouling can all be the result of different causes but, once a spark plug is fouled, it will not provide adequate voltage to the firing tip and that cylinder will not fire properly. Therefore, it is recommended that a plug be replaced once it is fouled.

Signs of fouling or excessive heat must be traced quickly to prevent further deterioration of performance and possible engine damage.

NGK “R” or resistor spark plugs use a 5k ohm ceramic resistor in the spark plug to suppress ignition noise generated during sparking.

NGK strongly recommends using resistor spark plugs in any vehicle that uses on-board computer systems to monitor or control engine performance. This is because resistor spark plugs reduce electromagnetic interference with on-board electronics.

They are also recommended on any vehicle that has other on-board electronic systems such as engine-management computers, two-way radios, GPS systems, depth finders or whenever recommended by the manufacturer.

In fact, using a non-resistor plug in certain applications can actually cause the engine to suffer undesirable side effects such as an erratic idle, high-rpm misfire, engine run-on, power drop off at certain rpm levels and abnormal combustion.

No, the electrode gap of NGK Spark Plugs is meticulously controlled when manufactured, and due to the very large selection of plugs, the electrode gap is set to suit the vehicle as recommended in our catalogue.

Modified engines with higher compression or forced induction will typically require smaller electrode gap settings (to ensure ignitability in these denser air/fuel mixtures) as the voltage requirement at the electrode gap is increased due to higher combustion pressures. As a rule, the more power you are making, the smaller the gap you will need. As an example, when you raise compression or add forced induction (a turbo system, nitrous or supercharger kit) you must reduce the gap (about 0.1mm for every 50 hp you add). However, when you add a high power ignition system (such as those offered by MSD, Crane, Nology) you can open the gap from 0.05mm-0.1mm.

Yes, the by-product of increased compression is the elevation in cylinder temperatures. This is why it is recommended to choose a spark plug suitable for your application. NGK Spark Plugs recommends dropping heat ranges and altering air-fuel mixtures and timing as needed. It is very important to dissipate the excess heat from the combustion chamber in order to prevent pre-ignition.

It is a common misconception that spark plugs create heat. They don’t. A heat range refers to how much heat a spark plug is capable of removing from the combustion chamber.

Selecting a spark plug with the proper heat range will ensure that the tip will maintain a temperature high enough to prevent fouling yet be cool enough to prevent pre-ignition. While there are many things that can cause pre-ignition, selecting a spark plug in the proper heat range will ensure that the spark plug itself is not a hot spot source.

Yes, humidity does affect spark plug temperature. As the humidity increases, the intake air mass decreases. This results in lower combustion pressures and temperatures, causing a decrease in the spark plug’s temperature.

Pre-ignition is defined as the ignition of the air-fuel mixture before desired ignition timing.

Detonation is a spark plug’s worst enemy. It can break insulators, ground and centre electrodes. Spark plug temperatures can reach in excess of 1600°C.

Detonation, in simple terms, is a violent uncontrolled burn of the air-fuel mixture, which occurs when excessive heat and cylinder pressure causes the air-fuel mixture to spontaneously ignite.

For nickel spark plugs the maximum is 0.1mm. We do not recommend adjusting the spark plug gap any further than this as the centre and ground electrodes won’t line up properly, hindering spark plug performance.

For precious metal spark plugs, NGK Spark Plugs (Australia) do not recommend adjusting the gaps as the fine centre electrode is not designed to withstand mechanical force and can easily be damaged.

Yes, ignition timing directly affects the firing end temperature of the spark plug. Advancing the ignition timing prolongs the time to compress the burning gases. The pre-ignition temperature also elevates gradually, since the pressure and temperature of the combustible mixture is low before ignition. Advancing your timing elevates firing end temperatures.

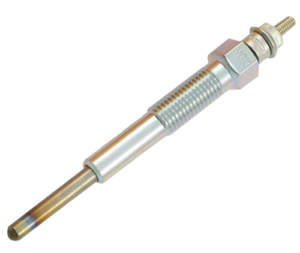

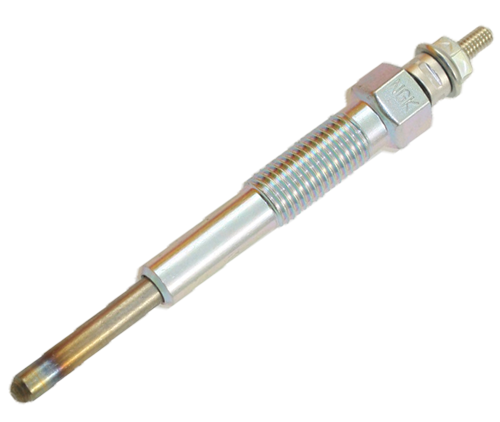

When choosing a glow plug, do not compromise on the following features:

- Safe start-up from low ambient temperatures

- Low emissions during warm-up phase

- Stable idling running before engine reaches operating temperature

- High quality coating on shell for high resistance to corrosion

- Unique shell design for excellent heat transfer, perfect gas tight sealing and high resistance to deformation and security of the heating coils

- Excellent post-glow function

- Long service life

Glow plugs are designed to reach their saturation temperature after a specific period of time at a given voltage application. This temperature has to be maintained for a specific period of time to provide stable combustion conditions. Diesel engine operation and toxic emissions can only be improved if the glow plug matches or exceeds the engine manufacturer’s specification.

NGK manufactures suitable glow plugs for a wide variety of engines and ECUs. NGK glow plugs can be broadly classified into two groups which are outlined below:

Metal glow plugs

These glow plugs have a heating coil enclosed within a tube that is made of heat-resistant material.

There are four types of metal glow plugs available:

- Standard sheathed-type glow plugs

- Fast heating or Rapid Glow, glow plugs

- QGS sheathed-type glow plugs

- Self-regulating (SRM) sheathed-type glow plugs

Ceramic glow plugs

The ceramic heating element of these glow plugs is completely encased in a ceramic insulating material.

There are three types of ceramic glow plug available:

- Self-regulating (SRC) glow plugs

- QGS glow plugs

- New high temperature ceramic (NHTC) glow plugs

The combination of ceramic heating element and coating allows ceramic glow plugs to reach higher temperatures than metal sheathed-type glow plugs, thus enabling the engine to reach operating temperature particularly quickly, even at temperatures well below freezing.

Due to the robust nature of the ceramic heating element and insulator, post-glow times of up to ten minutes can be employed.

A further advantage of ceramic glow plugs is that the cross sectional area of the heating portion can be made much smaller. This is a major advantage to modern diesel engines where space is severely restricted around the combustion chamber.

Metal and ceramic glow plugs are not interchangeable.

To ensure that a glow plug is functioning correctly, you should measure the resistance between the terminal and the metal casing.

For reliable results, you should make the following preparations:

- Ensure that your measuring instrument is capable of displaying even the most minimal testing voltages. The reason for this is that a QGS glow plug at ambient temperature only has a resistance of approximately 0.1Ω.

- Before taking the measurements, remove any rust, dirt, oil or lacquer from the thread of the glow plug.

- Ideally, you should check ceramic glow plugs without removing from the engine. This reduces the risk of damage as a result of dismantling.

Innovative glow plugs are a key component in effective pollution control. NGK recognised this and invested in ceramic glow plugs as a future market at a time when most people still considered the new technology to be uneconomical.

Their success has proven that this was the right strategy: EURO emission standards are becoming increasingly

more stringent and, in respect of exhaust emissions, require perfect interaction between all components of

the engine. They are also beneficial for the development of diesel engines which operate at a lower

compression ratio.

These engines are reliant on high-performance glow plugs, such as the NGK ceramic glow plugs, to meet these stringent emission regulations.

The higher the saturated temperature and the quicker it can get there, the shorter the engine start time and more stable idle reducing harmful exhaust gas emissions can be achieved.

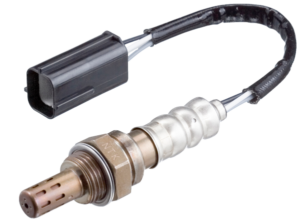

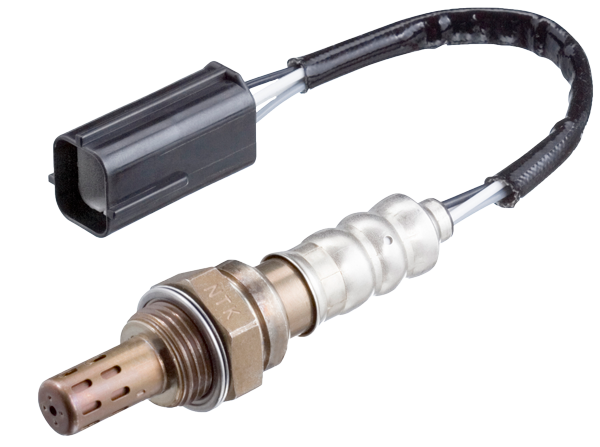

Sensors should be tested at every tune-up. In the interval periods, the following tips can show whether a sensor has reached the end of its service life:

- Poor fuel economy

- Higher exhaust emissions

- Surging and/or hesitation

- Rough idling

- Catalytic converter failure

Additionally, when the “Check Engine” light is illuminated, generally the oxygen sensor needs to be checked.

Failed and/or poorly operating oxygen sensors can cause a substantial drop in fuel economy. In addition, exhaust emissions can increase dramatically, and poor drivability may also result. Catalytic converters can also fail due to increased emissions.

On-board diagnostic (OBD) systems are in most cars and light trucks on the road today. During the ’70s and early 1980s manufacturers started using electronic controls to manage engine functions and diagnose problems. This was primarily to meet EPA emission standards. The original OBD standards in the late 1980s were derived from SAE standards for connectors and diagnostic test signals. OBD-II, a new standard introduced in the mid-’90s, provides virtually complete engine control, and also monitors parts of the chassis, body and accessory devices, as well as the diagnostic control network of the vehicle.

The Environmental Protection Agency is empowered to require manufacturers to build cars that meet increasingly more stringent emissions standards. OBD-II provides a universal inspection and diagnosis method to determine that the car is performing to OEM standards.

While an oxygen sensor can completely fail, this usually happens instantaneously, and is usually due to contamination. Most sensors slowly degrade in performance and send a false rich signal to the ECU, running the engine too lean.

Fuel additives and injector cleaners that are labelled as “oxygen sensor safe” may be used in sensor-equipped vehicles. Use of additives not labelled as “oxygen sensor safe” can damage your oxygen sensor.

Oxygen sensors measure the oxygen content in exhaust gas. Oxygen in exhaust gas accurately indicates how complete the combustion process is. This data is transmitted to the car’s ECU in real time. The ECU then adjusts the air-fuel ratio to keep the exhaust gas in a composition that permits effective treatment by the catalytic converter.

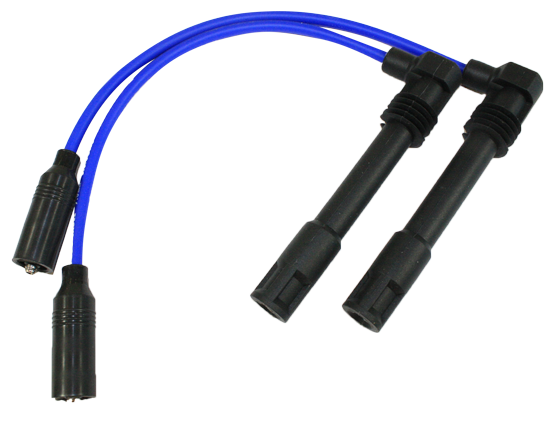

Ignition leads act as the electrical connection from ignition coil/distributor to spark plugs. They are

responsible for conducting the necessary voltage to spark plugs with as little loss or voltage-drop as

possible. The average ignition voltage required for combustion engines is within the high-voltage

range of up to 36,000 volts. To deliver the required voltage, ignition leads are used in conjunction with the below components – depending on the type of vehicle:

- A mechanical spark distributor and distributor cap.

- A fully electronic ignition module.

- A fully electronic semi-direct ignition or double spark ignition coil.

NGK ignition lead kits are manufactured from the highest quality of EPDM rubber (Ethylene

Propylene Diene Monomer) and silicone. Compared to PVC (Polyvinyl Chloride), these materials are

far more resistant to high temperatures >260°C, and oil or chemical contamination. It therefore

complies with the highest class for ignition lead manufacture in accordance with ISO 9001 standards.

Running along each NGK ignition lead is a unique stainless steel wound ferrite (fibreglass) spiral core

conductor. Encasing the spiral core is a conductive and magnetic silicone layer, a high-dielectric

silicone inner insulation layer, fibreglass fabric layer and then followed by a high-temperature

resistant silicone outer insulation layer. NGK’s ignition leads yield an extremely low resistance value

from 1,300 ohms per metre) that allows superior conductivity.

NGK ignition lead kits are manufactured from the highest quality of EPDM rubber (Ethylene

Propylene Diene Monomer) and silicone. Compared to PVC (Polyvinyl Chloride), these

materials are far more resistant to high temperatures >260°C, and oil or chemical

contamination. It therefore complies with the highest class for ignition lead manufacture in

accordance with ISO 9001 standards. Running along each NGK ignition lead is a unique

copper wound ferrite (fibreglass) spiral core conductor. Encasing the spiral core is a conductive

and magnetic silicone layer, a high-dielectric silicone inner insulation layer, fibreglass fabric

layer, a high-dielectric silicone middle insulation layer and then followed by a high-temperature

resistant silicone outer insulation layer.

NGK Ignition lead spark plug boots and tubes have been designed to match or exceed OE exacting

standards. Each ignition lead is fitted with a positive locking, corrosion resistant stainless steel

terminal end for a tight fit and maximum resistance to vibration and separation.

Due to excessive heat generated by an internal combustion engine, radiant heat surrounding an ignition lead spark plug tube can be in excess of 500°C. As a result some vehicle applications require heat-shield sleeve protection for their ignition lead spark plug boots or tubes. There are many varying styles of heat-shields as they are dependent on the design of the ignition lead spark plug boot or tube, and as such are not interchangeable. The three common heat-shield types include:

- 180° Heat Shield

- 90° Heat Shield

- Universal Heat Shield

LPG increases the required voltage to form a spark by 15% – 30% and considerably raises the risk of

cross-fire between ignition leads. This increase can result in engine backfire and potential damage

to air intake components. Poorly made ignition leads do not offer the required voltage resistance,

impedance and insulating properties to minimise cross-fire. Engine temperatures are also higher

with LPG compared to petrol. This occurs due to LPG’s reduced cooling effect. NGK Ignition Leads

with their unique variable pitch stainless steel wound ferrite (fibreglass) spiral core and high quality

inner and outer insulation layers are proven to be the best choice for LPG applications. NGK Ignition

Leads are compatible with LPG applications.

The essential function of the ignition coil is the delivery of high voltage, which jumps between the centre and ground electrode of the spark plug within a cylinder, generating the ignition spark. In the ignition process, the ignition coil plays a vital role in providing reliable ignition, allowing for the smooth and efficient operation of the engine.

The fundamental principle is the same for all ignition coils: A voltage in the high kilovolt range – up to 45,000 volts in modern vehicles – must be generated from a low battery voltage of 12 volts. Therefore, the voltage is transformed and multiplied. This principle relates to traditional cylinder ignition coils and modern block ignition coils or pencil coils.

The design of an ignition coil for the petrol engine is essentially identical for all ignition coil types from a schematic perspective. There are two coils in the interior of each ignition coil: the so-called primary coil, which is comprised of relatively thick copper wire, and the secondary coil, which is significantly longer and is produced of a relatively thin copper wire.

Ignition coils have a laminated Ferro-magnetic core, around which the primary and secondary coils are wound. The copper wire of this coil is insulated in order to prevent the voltage from jumping over from coil to coil and thus resulting in short-circuits.

The high-voltage pulse of an ignition coil arises in the secondary coil with the help of magnetic induction. For this purpose, the primary coil is first supplied with the battery current through the low-voltage connection of the ignition coil. A magnetic field is simultaneously formed around the primary coil. If this current flow is interrupted, the magnetic field collapses. It is this collapse which triggers a voltage pulse in the secondary coil.

The voltage pulse arising in the secondary coil is higher than the 12 volt battery voltage, which previously flowed through the primary coil. The reason: The secondary coil is wound with considerably finer wire and thus has a significantly higher number of windings than the primary coil. The so-called winding ratio is between 1:150 and 1:200, depending on the coil.

Apart from the winding ratio, there are additional factors which influence the actual level of the high-voltage pulses emitted. For example, the strength of the magnetic field arising in the primary coil plays an equally important role as that of the speed with which it collaborates. The density of the secondary coil, and the time remaining for the charge also have a strong influence on the end result.

Ignition coil technology can be split into two fundamental operating principles: ‘single spark technology’ and ‘dual spark technology’

Single Spark Technology

Single spark ignition coils only release one high voltage pulse via one high voltage output. The classic

form of an ignition coil with single spark technology is the distributor ignition coil. This type of ignition coil always releases its ignition energy to the mechanical ignition distributor, which controls distribution to the relevant spark plug in accordance with the firing order.

Today, single spark technology is more popular for automotive manufacturers, but in the form of pencil coils. With this type, each ignition coil supplies only one cylinder.

Dual Spark Technology

Dual spark ignition coils have multiple high voltage outputs which supply two spark plugs with ignition energy simultaneously.

When applied to the classic firing order of a four cylinder engine, cylinders (1 and 4) and cylinders (2 and 3) each receives high voltage pulses simultaneously. But due to the different timing, only one of these cylinders is on the power stroke, during which the air-fuel mixture is ignited. The other cylinder is on the exhaust stroke, where another spark is triggered in order to complete the electrical circuit, but this extinguishes with no effect. For this reason, it is known as a ‘wasted spark’.

There are several factors—such as thread reach, thread diameter, the insulator nose projection and whether the spark plug incorporates a gasket or is of the conical type—to consider when choosing the correct spark plug for your needs.

In most cases, it is not until the engine is modified, or the compression is raised significantly, that stock ignition systems and spark plugs begin to show signs of being inadequate. At this point, a variety of factors determine which spark plug will be best suited for a particular configuration. In these modified engines, specific electrode/tip combinations, electrode materials and colder heat ranges can provide measurable gains in power. If your vehicle has had extensive modifications, it would be best to seek the advice of the manufacturer of your vehicle, the aftermarket supplier who manufactured your modifications or your service technician.

A common misconception is that changing spark plugs will result in a large power increase. In most cases, removing even seriously worn out spark plugs will only result in very modest power gains, typically about 1-2% of total engine output. This could be even less for computer-controlled vehicles, primarily because most newer vehicles have more powerful ignition systems and the vehicle’s computer can make adjustments so that vehicle operation seems smoother and more seamless.

Many people think that simply supplying more spark to the firing tip can and will combust more fuel. What they don’t understand is that most newer car engines are so efficient that they are already burning all of the available fuel. Simply adding more spark voltage can’t burn more fuel because there is no more fuel to burn.

When a stock or near-stock engine is given a fresh set of spark plugs, peak efficiency is restored. The power gains that come from this restored state of tune are usually minimal. Any company that tells you that their spark plug will provide significant gains in power in a stock or near-stock engine is making blanket statements that may not be supportable.

Unfortunately, there is no single answer to this question. As spark plugs grow older, they lose their sharp edges as material from the centre and ground electrodes is slowly eroded away. As the gap between these two points grows, the voltage required to bridge the gap increases proportionately. Even the best ignition systems will be strained to supply enough voltage to completely burn the fuel. It is at this point, when fuel is being left unburned, that the time has come to change spark plugs.

Replacing worn out spark plugs with new ones (with sharp new edges) effectively restores the ignition system’s efficiency. Misfires are reduced, power is restored, economy of operation is enhanced and emissions are reduced.

The best guide is the manufacturer’s recommendation for your vehicle, as this particular service varies from brand to brand and model to model. In the absence of this information or in conjunction with it, you can rely on the advice of a service technician who is familiar with your type of vehicle. In the best of all worlds, this would be a service technician who is also familiar with the vehicle you own. If you find a good service technician, whether dealer or independent, stick with them. The better he knows your personal vehicle, the better he will be able to diagnose and service it. The end result is very much like a doctor-patient relationship and, in the long run, you will have a healthier vehicle.

It depends on the modifications. The term “modified” refers to those engines that have received bolt-on improvements that may or may not raise the engine’s total compression ratio. These can include turbo charging, supercharging, nitrous oxide injection, the use of smaller-chambered cylinder heads, modified piston configurations, free-flowing cylinder heads, change of induction components and/or the use of different fuel types and octane. These kinds of modifications generally require a change from stock spark plugs.

Modifications that will typically not require specialized plugs (in most cases the factory installed plug will be more than adequate) include adding a free-flowing air filter, headers, mufflers and rear-end gears. Basically, any modification that does not alter the overall compression ratio will not usually necessitate changing plug types or heat ranges. Such minor modifications will not significantly increase the amount of heat in the combustion chamber, hence, a plug change is probably not warranted.

However, when compression is raised, along with the added power comes added heat. Since spark plugs must remove heat and a modified engine makes more heat, the spark plug must remove more heat. A colder heat range spark plug must be selected and plug gaps should be adjusted smaller to ensure proper ignitability in this denser air-fuel mixture.

Typically, for every 75-100 hp you add, you should go one step colder on the spark plug’s heat range. A hotter heat range is not usually recommended except when severe oil or fuel fouling is occurring.

Being able to “read” a spark plug can be a valuable tuning aid. By examining the insulator firing nose colour, an experienced engine tuner can determine a great deal about the engine’s overall operating condition.

In general, a light tan/grey colour tells you that the spark plug is operating at optimum temperature and that the engine is in good condition. Dark colouring, such as heavy black wet or dry deposits, can indicate an overly rich condition, too cold a heat range spark plug, a possible vacuum leak, low compression, overly retarded timing or too large a plug gap.

If the deposits are wet, it can be an indication of a breached head gasket, poor oil control from ring or valve train problems or an extremely rich condition—depending on the nature of the liquid present at the firing tip.

A spark plug is considered fouled when the insulator nose at the firing tip becomes coated with a foreign substance such as fuel, oil or carbon. This coating makes it easier for the voltage to follow along the insulator nose, leach back down into the metal shell and ground out rather than bridging the gap and firing normally.

Many factors can contribute to spark plug fouling. The air-fuel ratio may be too rich as a result of incorrect carburettor adjustment or a poorly performing fuel injection system. Worn piston rings or valve seals may allow too much oil to leak into the combustion chamber, leading to oil fouling. The ignition system may not be performing properly. Prolonged idling or continuous low-speed driving may keep the spark plug from reaching its optimum operating temperature. Using too cold a spark plug can lead to the same problem. Finally, a dirty air cleaner can create a too-rich condition which can lead to fouling.

Fuel, oil and carbon fouling can all be the result of different causes but, once a spark plug is fouled, it will not provide adequate voltage to the firing tip and that cylinder will not fire properly. Therefore, it is recommended that a plug be replaced once it is fouled.

Signs of fouling or excessive heat must be traced quickly to prevent further deterioration of performance and possible engine damage.

NGK “R” or resistor spark plugs use a 5k ohm ceramic resistor in the spark plug to suppress ignition noise generated during sparking.

NGK strongly recommends using resistor spark plugs in any vehicle that uses on-board computer systems to monitor or control engine performance. This is because resistor spark plugs reduce electromagnetic interference with on-board electronics.

They are also recommended on any vehicle that has other on-board electronic systems such as engine-management computers, two-way radios, GPS systems, depth finders or whenever recommended by the manufacturer.

In fact, using a non-resistor plug in certain applications can actually cause the engine to suffer undesirable side effects such as an erratic idle, high-rpm misfire, engine run-on, power drop off at certain rpm levels and abnormal combustion.

No, the electrode gap of NGK Spark Plugs is meticulously controlled when manufactured, and due to the very large selection of plugs, the electrode gap is set to suit the vehicle as recommended in our catalogue.

Modified engines with higher compression or forced induction will typically require smaller electrode gap settings (to ensure ignitability in these denser air/fuel mixtures) as the voltage requirement at the electrode gap is increased due to higher combustion pressures. As a rule, the more power you are making, the smaller the gap you will need. As an example, when you raise compression or add forced induction (a turbo system, nitrous or supercharger kit) you must reduce the gap (about 0.1mm for every 50 hp you add). However, when you add a high power ignition system (such as those offered by MSD, Crane, Nology) you can open the gap from 0.05mm-0.1mm.

Yes, the by-product of increased compression is the elevation in cylinder temperatures. This is why it is recommended to choose a spark plug suitable for your application. NGK Spark Plugs recommends dropping heat ranges and altering air-fuel mixtures and timing as needed. It is very important to dissipate the excess heat from the combustion chamber in order to prevent pre-ignition.

It is a common misconception that spark plugs create heat. They don’t. A heat range refers to how much heat a spark plug is capable of removing from the combustion chamber.

Selecting a spark plug with the proper heat range will ensure that the tip will maintain a temperature high enough to prevent fouling yet be cool enough to prevent pre-ignition. While there are many things that can cause pre-ignition, selecting a spark plug in the proper heat range will ensure that the spark plug itself is not a hot spot source.

Yes, humidity does affect spark plug temperature. As the humidity increases, the intake air mass decreases. This results in lower combustion pressures and temperatures, causing a decrease in the spark plug’s temperature.

Pre-ignition is defined as the ignition of the air-fuel mixture before desired ignition timing.

Detonation is a spark plug’s worst enemy. It can break insulators, ground and centre electrodes. Spark plug temperatures can reach in excess of 1600°C.

Detonation, in simple terms, is a violent uncontrolled burn of the air-fuel mixture, which occurs when excessive heat and cylinder pressure causes the air-fuel mixture to spontaneously ignite.

For nickel spark plugs the maximum is 0.1mm. We do not recommend adjusting the spark plug gap any further than this as the centre and ground electrodes won’t line up properly, hindering spark plug performance.

For precious metal spark plugs, NGK Spark Plugs (Australia) do not recommend adjusting the gaps as the fine centre electrode is not designed to withstand mechanical force and can easily be damaged.

Yes, ignition timing directly affects the firing end temperature of the spark plug. Advancing the ignition timing prolongs the time to compress the burning gases. The pre-ignition temperature also elevates gradually, since the pressure and temperature of the combustible mixture is low before ignition. Advancing your timing elevates firing end temperatures.

When choosing a glow plug, do not compromise on the following features:

- Safe start-up from low ambient temperatures

- Low emissions during warm-up phase

- Stable idling running before engine reaches operating temperature

- High quality coating on shell for high resistance to corrosion

- Unique shell design for excellent heat transfer, perfect gas tight sealing and high resistance to deformation and security of the heating coils

- Excellent post-glow function

- Long service life

Glow plugs are designed to reach their saturation temperature after a specific period of time at a given voltage application. This temperature has to be maintained for a specific period of time to provide stable combustion conditions. Diesel engine operation and toxic emissions can only be improved if the glow plug matches or exceeds the engine manufacturer’s specification.

NGK manufactures suitable glow plugs for a wide variety of engines and ECUs. NGK glow plugs can be broadly classified into two groups which are outlined below:

Metal glow plugs

These glow plugs have a heating coil enclosed within a tube that is made of heat-resistant material.

There are four types of metal glow plugs available:

- Standard sheathed-type glow plugs

- Fast heating or Rapid Glow, glow plugs

- QGS sheathed-type glow plugs

- Self-regulating (SRM) sheathed-type glow plugs

Ceramic glow plugs

The ceramic heating element of these glow plugs is completely encased in a ceramic insulating material.

There are three types of ceramic glow plug available:

- Self-regulating (SRC) glow plugs

- QGS glow plugs

- New high temperature ceramic (NHTC) glow plugs

The combination of ceramic heating element and coating allows ceramic glow plugs to reach higher temperatures than metal sheathed-type glow plugs, thus enabling the engine to reach operating temperature particularly quickly, even at temperatures well below freezing.

Due to the robust nature of the ceramic heating element and insulator, post-glow times of up to ten minutes can be employed.

A further advantage of ceramic glow plugs is that the cross sectional area of the heating portion can be made much smaller. This is a major advantage to modern diesel engines where space is severely restricted around the combustion chamber.

Metal and ceramic glow plugs are not interchangeable.

To ensure that a glow plug is functioning correctly, you should measure the resistance between the terminal and the metal casing.

For reliable results, you should make the following preparations:

- Ensure that your measuring instrument is capable of displaying even the most minimal testing voltages. The reason for this is that a QGS glow plug at ambient temperature only has a resistance of approximately 0.1Ω.

- Before taking the measurements, remove any rust, dirt, oil or lacquer from the thread of the glow plug.

- Ideally, you should check ceramic glow plugs without removing from the engine. This reduces the risk of damage as a result of dismantling.

Innovative glow plugs are a key component in effective pollution control. NGK recognised this and invested in ceramic glow plugs as a future market at a time when most people still considered the new technology to be uneconomical.

Their success has proven that this was the right strategy: EURO emission standards are becoming increasingly

more stringent and, in respect of exhaust emissions, require perfect interaction between all components of

the engine. They are also beneficial for the development of diesel engines which operate at a lower

compression ratio.

These engines are reliant on high-performance glow plugs, such as the NGK ceramic glow plugs, to meet these stringent emission regulations.

The higher the saturated temperature and the quicker it can get there, the shorter the engine start time and more stable idle reducing harmful exhaust gas emissions can be achieved.

Sensors should be tested at every tune-up. In the interval periods, the following tips can show whether a sensor has reached the end of its service life:

- Poor fuel economy

- Higher exhaust emissions

- Surging and/or hesitation

- Rough idling

- Catalytic converter failure

Additionally, when the “Check Engine” light is illuminated, generally the oxygen sensor needs to be checked.

Failed and/or poorly operating oxygen sensors can cause a substantial drop in fuel economy. In addition, exhaust emissions can increase dramatically, and poor drivability may also result. Catalytic converters can also fail due to increased emissions.

On-board diagnostic (OBD) systems are in most cars and light trucks on the road today. During the ’70s and early 1980s manufacturers started using electronic controls to manage engine functions and diagnose problems. This was primarily to meet EPA emission standards. The original OBD standards in the late 1980s were derived from SAE standards for connectors and diagnostic test signals. OBD-II, a new standard introduced in the mid-’90s, provides virtually complete engine control, and also monitors parts of the chassis, body and accessory devices, as well as the diagnostic control network of the vehicle.

The Environmental Protection Agency is empowered to require manufacturers to build cars that meet increasingly more stringent emissions standards. OBD-II provides a universal inspection and diagnosis method to determine that the car is performing to OEM standards.

While an oxygen sensor can completely fail, this usually happens instantaneously, and is usually due to contamination. Most sensors slowly degrade in performance and send a false rich signal to the ECU, running the engine too lean.

Fuel additives and injector cleaners that are labelled as “oxygen sensor safe” may be used in sensor-equipped vehicles. Use of additives not labelled as “oxygen sensor safe” can damage your oxygen sensor.

Oxygen sensors measure the oxygen content in exhaust gas. Oxygen in exhaust gas accurately indicates how complete the combustion process is. This data is transmitted to the car’s ECU in real time. The ECU then adjusts the air-fuel ratio to keep the exhaust gas in a composition that permits effective treatment by the catalytic converter.

Ignition leads act as the electrical connection from ignition coil/distributor to spark plugs. They are

responsible for conducting the necessary voltage to spark plugs with as little loss or voltage-drop as

possible. The average ignition voltage required for combustion engines is within the high-voltage

range of up to 36,000 volts. To deliver the required voltage, ignition leads are used in conjunction with the below components – depending on the type of vehicle:

- A mechanical spark distributor and distributor cap.

- A fully electronic ignition module.

- A fully electronic semi-direct ignition or double spark ignition coil.

NGK ignition lead kits are manufactured from the highest quality of EPDM rubber (Ethylene

Propylene Diene Monomer) and silicone. Compared to PVC (Polyvinyl Chloride), these materials are

far more resistant to high temperatures >260°C, and oil or chemical contamination. It therefore

complies with the highest class for ignition lead manufacture in accordance with ISO 9001 standards.

Running along each NGK ignition lead is a unique stainless steel wound ferrite (fibreglass) spiral core

conductor. Encasing the spiral core is a conductive and magnetic silicone layer, a high-dielectric

silicone inner insulation layer, fibreglass fabric layer and then followed by a high-temperature

resistant silicone outer insulation layer. NGK’s ignition leads yield an extremely low resistance value

from 1,300 ohms per metre) that allows superior conductivity.

NGK ignition lead kits are manufactured from the highest quality of EPDM rubber (Ethylene

Propylene Diene Monomer) and silicone. Compared to PVC (Polyvinyl Chloride), these

materials are far more resistant to high temperatures >260°C, and oil or chemical

contamination. It therefore complies with the highest class for ignition lead manufacture in

accordance with ISO 9001 standards. Running along each NGK ignition lead is a unique

copper wound ferrite (fibreglass) spiral core conductor. Encasing the spiral core is a conductive

and magnetic silicone layer, a high-dielectric silicone inner insulation layer, fibreglass fabric

layer, a high-dielectric silicone middle insulation layer and then followed by a high-temperature

resistant silicone outer insulation layer.

NGK Ignition lead spark plug boots and tubes have been designed to match or exceed OE exacting

standards. Each ignition lead is fitted with a positive locking, corrosion resistant stainless steel

terminal end for a tight fit and maximum resistance to vibration and separation.

Due to excessive heat generated by an internal combustion engine, radiant heat surrounding an ignition lead spark plug tube can be in excess of 500°C. As a result some vehicle applications require heat-shield sleeve protection for their ignition lead spark plug boots or tubes. There are many varying styles of heat-shields as they are dependent on the design of the ignition lead spark plug boot or tube, and as such are not interchangeable. The three common heat-shield types include:

- 180° Heat Shield

- 90° Heat Shield

- Universal Heat Shield

LPG increases the required voltage to form a spark by 15% – 30% and considerably raises the risk of

cross-fire between ignition leads. This increase can result in engine backfire and potential damage

to air intake components. Poorly made ignition leads do not offer the required voltage resistance,

impedance and insulating properties to minimise cross-fire. Engine temperatures are also higher

with LPG compared to petrol. This occurs due to LPG’s reduced cooling effect. NGK Ignition Leads

with their unique variable pitch stainless steel wound ferrite (fibreglass) spiral core and high quality

inner and outer insulation layers are proven to be the best choice for LPG applications. NGK Ignition

Leads are compatible with LPG applications.

The essential function of the ignition coil is the delivery of high voltage, which jumps between the centre and ground electrode of the spark plug within a cylinder, generating the ignition spark. In the ignition process, the ignition coil plays a vital role in providing reliable ignition, allowing for the smooth and efficient operation of the engine.

The fundamental principle is the same for all ignition coils: A voltage in the high kilovolt range – up to 45,000 volts in modern vehicles – must be generated from a low battery voltage of 12 volts. Therefore, the voltage is transformed and multiplied. This principle relates to traditional cylinder ignition coils and modern block ignition coils or pencil coils.

The design of an ignition coil for the petrol engine is essentially identical for all ignition coil types from a schematic perspective. There are two coils in the interior of each ignition coil: the so-called primary coil, which is comprised of relatively thick copper wire, and the secondary coil, which is significantly longer and is produced of a relatively thin copper wire.

Ignition coils have a laminated Ferro-magnetic core, around which the primary and secondary coils are wound. The copper wire of this coil is insulated in order to prevent the voltage from jumping over from coil to coil and thus resulting in short-circuits.

The high-voltage pulse of an ignition coil arises in the secondary coil with the help of magnetic induction. For this purpose, the primary coil is first supplied with the battery current through the low-voltage connection of the ignition coil. A magnetic field is simultaneously formed around the primary coil. If this current flow is interrupted, the magnetic field collapses. It is this collapse which triggers a voltage pulse in the secondary coil.

The voltage pulse arising in the secondary coil is higher than the 12 volt battery voltage, which previously flowed through the primary coil. The reason: The secondary coil is wound with considerably finer wire and thus has a significantly higher number of windings than the primary coil. The so-called winding ratio is between 1:150 and 1:200, depending on the coil.

Apart from the winding ratio, there are additional factors which influence the actual level of the high-voltage pulses emitted. For example, the strength of the magnetic field arising in the primary coil plays an equally important role as that of the speed with which it collaborates. The density of the secondary coil, and the time remaining for the charge also have a strong influence on the end result.

Ignition coil technology can be split into two fundamental operating principles: ‘single spark technology’ and ‘dual spark technology’

Single Spark Technology

Single spark ignition coils only release one high voltage pulse via one high voltage output. The classic

form of an ignition coil with single spark technology is the distributor ignition coil. This type of ignition coil always releases its ignition energy to the mechanical ignition distributor, which controls distribution to the relevant spark plug in accordance with the firing order.

Today, single spark technology is more popular for automotive manufacturers, but in the form of pencil coils. With this type, each ignition coil supplies only one cylinder.

Dual Spark Technology

Dual spark ignition coils have multiple high voltage outputs which supply two spark plugs with ignition energy simultaneously.

When applied to the classic firing order of a four cylinder engine, cylinders (1 and 4) and cylinders (2 and 3) each receives high voltage pulses simultaneously. But due to the different timing, only one of these cylinders is on the power stroke, during which the air-fuel mixture is ignited. The other cylinder is on the exhaust stroke, where another spark is triggered in order to complete the electrical circuit, but this extinguishes with no effect. For this reason, it is known as a ‘wasted spark’.