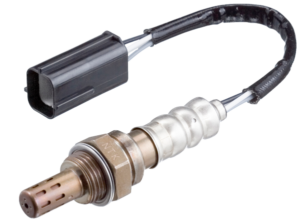

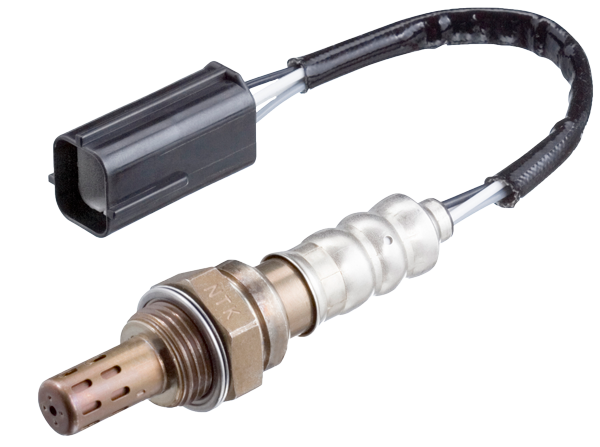

Visual Inspection

Visual inspection alone is not usually sufficient to determine if an oxygen sensor is functioning correctly. However, the following are considered mandatory basic checks:

The lead wire andBelow are some examples of damaged sensors and an indication of what might have been the possible cause. The cause should be rectified and the sensor changed to avoid further problems including damage to the catalytic converter.

Excessive Carbon or Oil Deposits

Excessive carbon and oil deposits can damage the sensor. Carbon deposits can clog the sensor and effect its response time. The cause can be

Excessive White or Grey Deposits

Excessive deposits such as these indicates that fuel additives are being used or the engine is burning oil. Certain components in the fuel additives

Shiny Deposits

Shiny Deposits indicate the presents of lead. Lead attacks the platinum on the sensor and in the catalyst. The sensor should be changed and only unleaded fuel

Grommet Pulled Out

The grommet protects the sensor from damage due to water intrusion into the sensor body. Abnormal tension on the wiring loom is the likely cause of

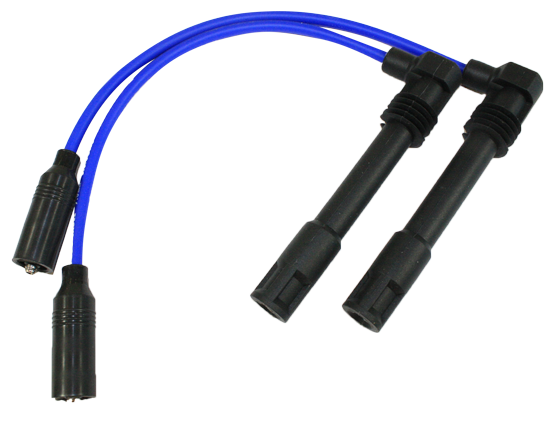

Frayed and Broken Lead Wire

If the wiring loom is subjected to abnormal tension it is possible for the wires to fray and / or break off. The lead

Water Inside Connecter and / or Rust on Terminals

Check the electrical terminal and the connector sealing. Also check the connection between the sensor and ECU.

Notice: Undefined offset: 25 in /home/ngknewzealand/public_html/wp-content/themes/ngk-theme/single-technical_info.php on line 34

Notice: Undefined offset: 26 in /home/ngknewzealand/public_html/wp-content/themes/ngk-theme/single-technical_info.php on line 34

Notice: Undefined offset: 27 in /home/ngknewzealand/public_html/wp-content/themes/ngk-theme/single-technical_info.php on line 34